What is on-shelf availability?

On-shelf availability is the volume of a specific product that is available on the shelf at any given time.

And it is a key metric that every retailer should know in order to offer a frictionless customer experience.

When you understand exactly what stock is currently sitting on the shelf, you can restock in a timely manner, avoiding out-of-stocks that have a dire impact on the customer experience.

Understanding your on-shelf availability also improves the re-ordering and supply process, offering an insight into how quickly a specific item sells when it is available in-store.

This in turn increases in-store efficiency by improving sales volumes, reducing waste, and giving an additional insight into what stock moves quickly or which items might need to be discounted because they are slow to sell.

Why on-shelf availability matters to the customer

While e-commerce has increased in the past decade and particularly the last few years, the physical experience of walking into a store, seeing a product in person and purchasing it immediately continue to be significant drawcards for shoppers and are some of the main reasons bricks and mortar retail continues to thrive.

And this immediacy is key. Often customers will research a product online and check whether it’s available, prior to visiting a specific store in-person.

The expectation is that product will be on the shelf, will be easy to find, and will be available for purchase quickly.

This is why understanding your on-shelf availability is so critical. Customers quickly become frustrated if they can’t find what they’re looking for, which affects the customer experience and ultimately impacts brand loyalty.

The following statistics illustrate just how dire the impact of lack of on-shelf availability can be:

- Out of stock events cost the Australian retail industry $14 billion in lost opportunity annually (Adyen)

- 83 per cent of consumers have chosen to leave a store and not make a purchase due to the item they seek being unavailable (Adyen)

- A third of people will then purchase the item they need elsewhere (On-shelf availability in retailing)

- A quarter will buy a different brand (On-shelf availability in retailing)

That’s a poor retail experience for the customer, a profit loss for the retailer, and a negative consequence for a brand.

The challenge of on-shelf availability

While on-shelf availability is critical, it’s often a challenging metric to manage, with a range of issues affecting what stock is on the shelf at a specific time.

However, within a retail operation, shortage of stock on the shelf comes down to four key factors:

- Slow replenishment times

The reality is the majority of on-shelf availability issues come down to simple inefficiency in-store. The items might be in the storeroom or a nearby warehouse, but they fail to make it to the shelves because staff haven’t noticed the product has run out.

In a time-poor era where staff may be busy or a product is in demand, they might also not have found the time to check then replenish products that are running low on the shelf.

Fixing this involves a commitment to stock visibility, whether that’s through technology, better systems and procedures, or increased staffing.

- Inaccurate forecasting

Retail often involves a fine balancing act of carrying just the right volume of the right product while also anticipating how in-demand that product will be in the future.

And sometimes out of stocks come down to the simple fact retailers failed to anticipate their customer’s needs.

In this case stock is not available on the shelf because it either hasn’t been ordered or the store is waiting on product delivery.

And this is where predictive analytics offer a viable solution, allowing retailers to anticipate which products will be in demand at what time.

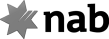

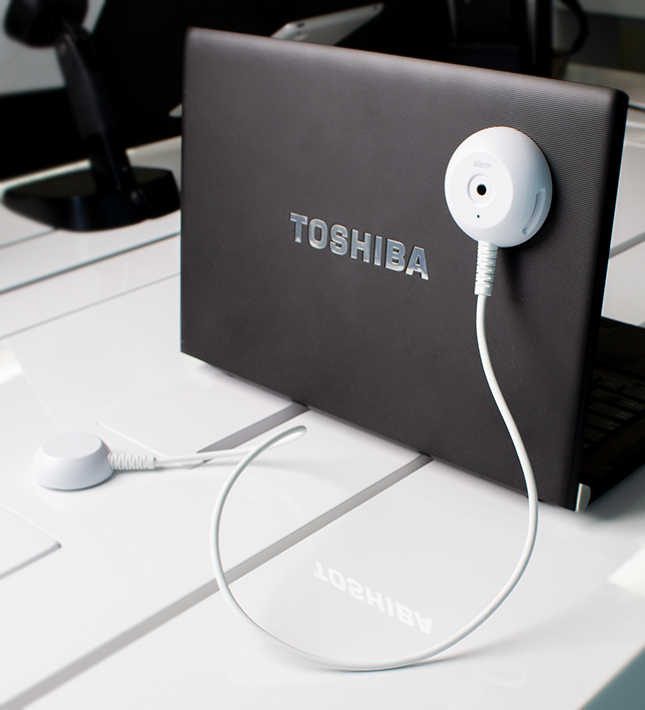

- Retail loss

Shoplifting, employee theft, and miscellaneous error all have the potential to result in stock being unavailable on the shelf. And in these instances, that lack of availability may be unexpected.

While a store’s inventory may indicate the item should be available, due to theft or error, it is not.

Solving this problem comes down to good retail loss prevention along with frequent inventory counting. It can also be resolved with a greater commitment to on-shelf stock visibility.

- Supply chain issues

The supply chain has always been potential weak link in mitigating out of stocks, and the reality is the current climate sees supply chain issues more of a challenge for the retail sector than ever before.

When there are delays in the supply chain, it is likely to result in out of stocks. It is also likely to see products arriving at the wrong time, resulting in stores carrying outdated or discontinued items, which may then need to be discounted.

Solving the on-shelf availability challenge

Solving the challenge of monitoring and managing on-shelf availability requires a multi-level approach that encompasses restocking processes and procedures, predictive analytics and good supply chain management.

However, the real solution to the problems starts at the shelf itself where staff should be paying attention to items that are running low or are in-demand.

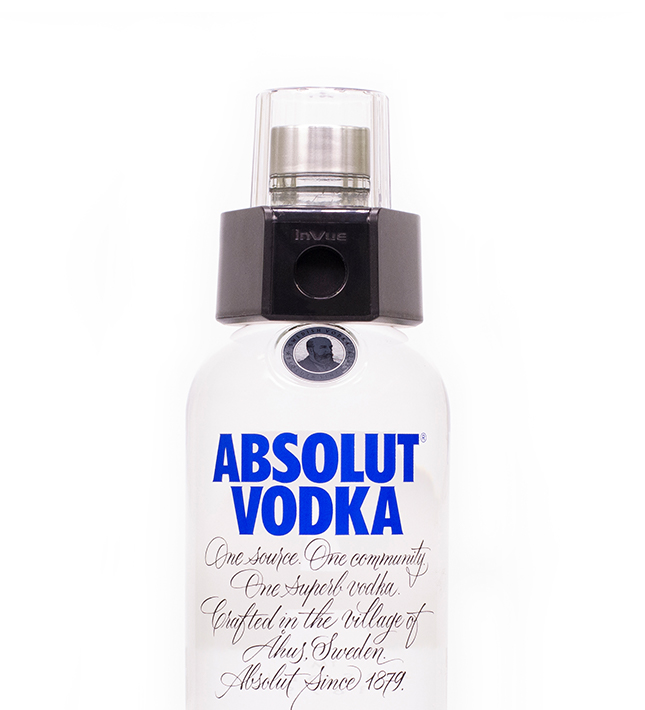

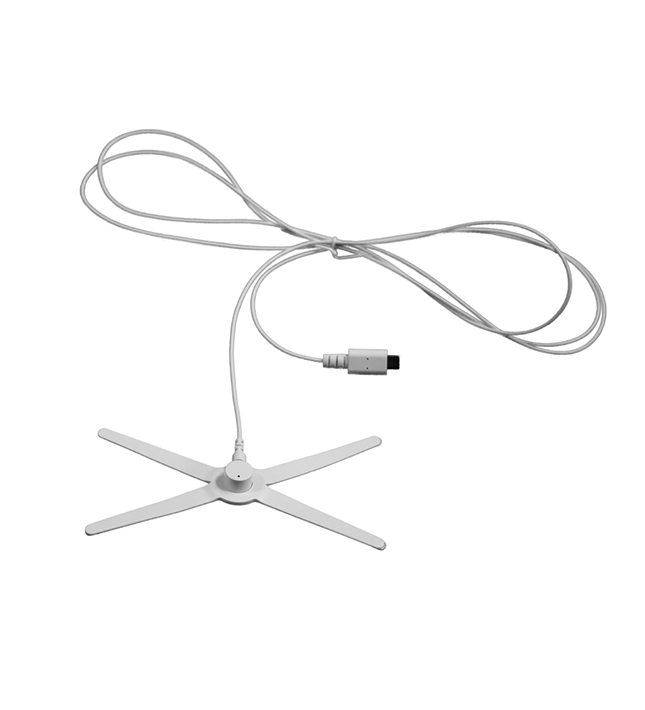

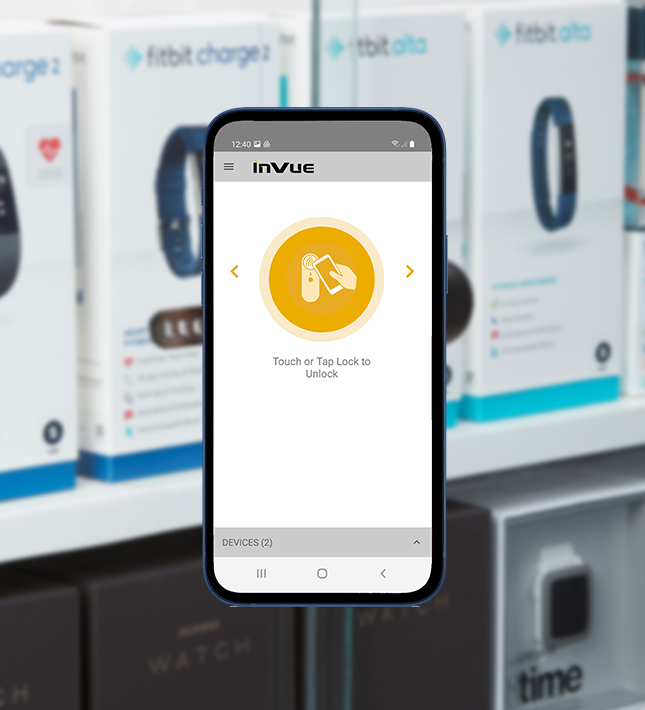

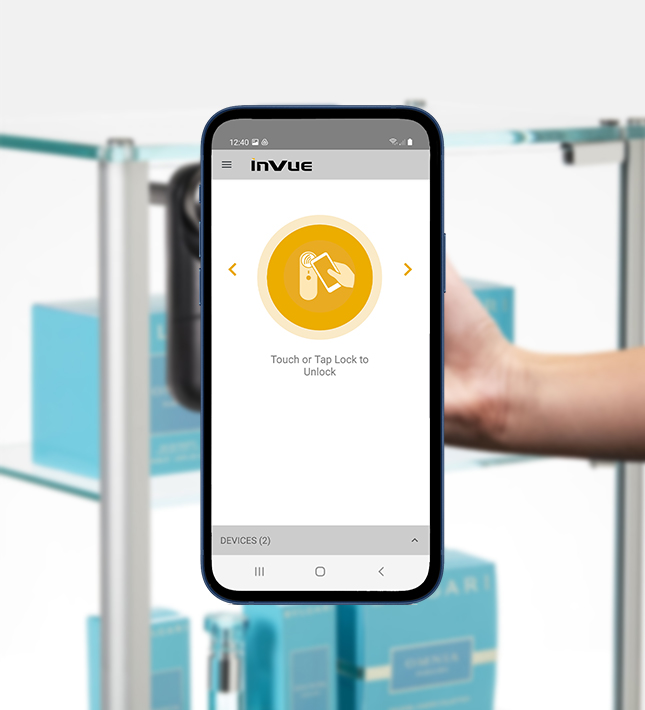

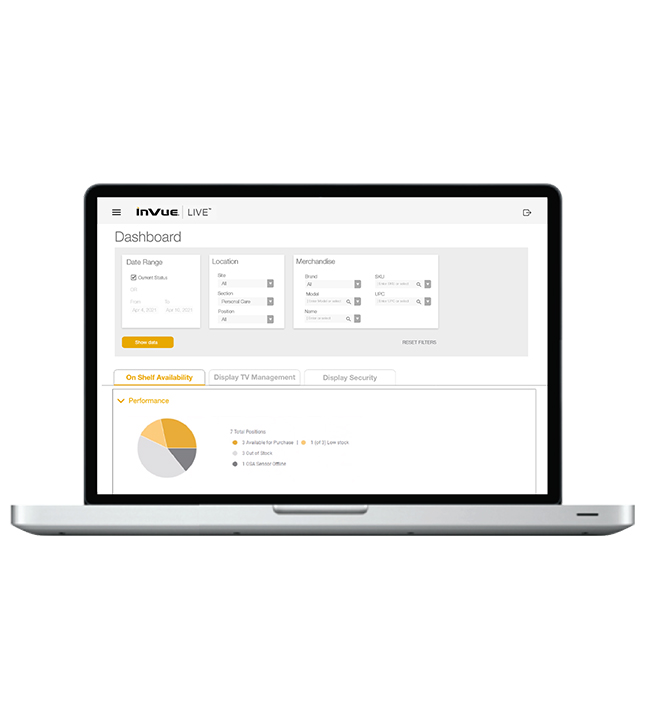

That’s where technology plays a vital role, using shelf sensors to alert staff to items that require restocking.

And this technology is both affordable to implement and easy to use.

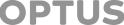

On-Shelf Availability sensors are unobtrusive, real-time sensors that can be positioned on the shelf to monitor the product and alert staff when that product is no longer available.

It allows for faster shelf-restocking, greater insight into products that are proving popular and further assists with inventory management while improving the overall customer experience.

You can view these sensors and see just how easily they solve the on-shelf availability challenge here.