It impacts the customer through out of stocks, inhibits the ability to fulfil e-commerce orders, results in missed sales, and ultimately can damage a retailer’s reputation.

So, is there an inventory solution? The short answer is yes, and it takes a couple of forms.

Inventory weak spots

The trouble with inventory is that it has multiple weak spots, including:

- Over-ordering, under-ordering, or inaccurate communication with your supplier

- Supply delays and transport issues

- Loss or breakage in the supply chain

- Inaccurate reconciliation at the point of delivery

- Inadequate systems, procedures, or storage options in the warehouse

- Inaccurate, incomplete, or irregular inventory counting across the retail floor and warehouse

- Inaccurate or incomplete returns

- Shoplifting, employee theft, human error, and miscellaneous loss

The fallout from an inventory problem

The biggest issue with an inventory problem is that it creates missed sales. A retailer or customer believes an item is in stock only to find that it isn’t or can’t be located and the customer’s order cannot be fulfilled.

And these out of stocks affect both the in-store experience and e-commerce, taking a major toll on a retailer’s bottom line.

The out of stock cost

In Australia, out of stock events are estimated to cost retailers $14 billion in lost retail opportunity, with a report by Adyen indicating 83 per cent of shoppers had chosen to leave a store and not make a purchase due to an item they wanted being out of stock.

The overstock issue

On the other side of the coin, an inventory problem can lead to overstocks, and this too is a costly issue.

An overstock occurs when retailers have too much surplus stock of a product on hand, which creates issues for the warehouse and the retail store.

Overstocks are usually due to overestimating demand for a product but ultimately, those products take up valuable warehouse space that could be used for products in higher demand.

Eventually these items are often heavily discounted in order to clear the oversupply.

So, what’s the solution?

The inventory solution

Tackling an inventory problem requires a multi-pronged approach involving technology, policy and procedure, and a commitment to obtaining clear insights into what’s going on throughout your retail operation.

Technology

For retailers looking to nip an inventory problem in the bud, technology is the first line of defence. So, let’s take a look at just a few of the tech tools available…

RFID

Tools like RFID tagging help retailers track inventory throughout the supply chain, offering greater inventory accuracy from the point of manufacture right through to delivery and beyond.

In fact, recent research found RFID offered 99.9 per cent supply chain accuracy, compared to traditional barcode accuracy of just 31 per cent.

Meanwhile, RFID also allows for real-time inventory counting which can be relayed to the Point of Sale (POS), so a retailer has accurate insight into exactly what stock is on hand and where its located.

This, in turn can also be used to trigger alerts when more stock is required.

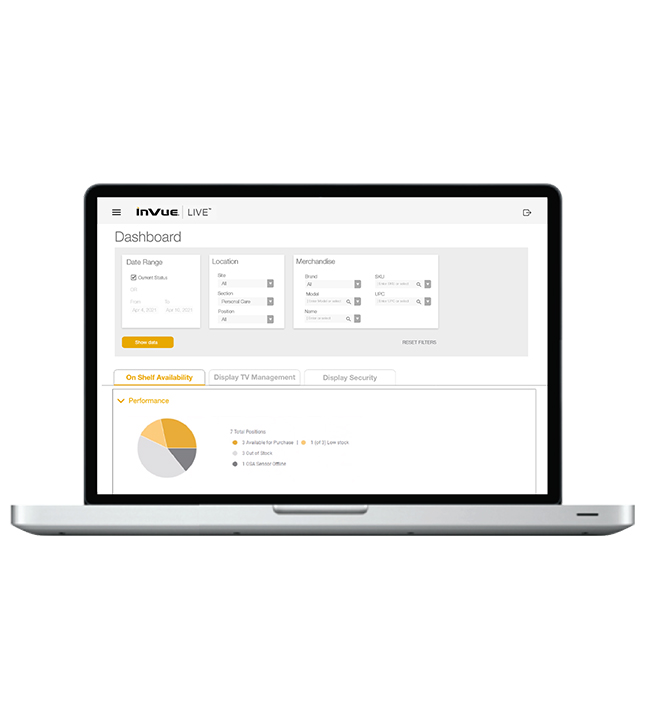

Analytics

Analytics is a pretty broad term, but basically it involves harnessing data to gain an insight into what’s happening instore and online at any moment in time.

In many ways analytics is a retail ecosystem that ties together data generated from the Point of Sale with other tools like traffic counting, seasonal trends, online search trends, ordering, and accurate available inventory.

Together it helps retailers plan what is likely to happen based on historic data and also offers real time insight into exactly what’s occurring now.

The key here is ensuring this data is linked. For example, inventory counting should not occur in isolation from sales data provided by the POS, which should also be linked in with e-commerce insight.

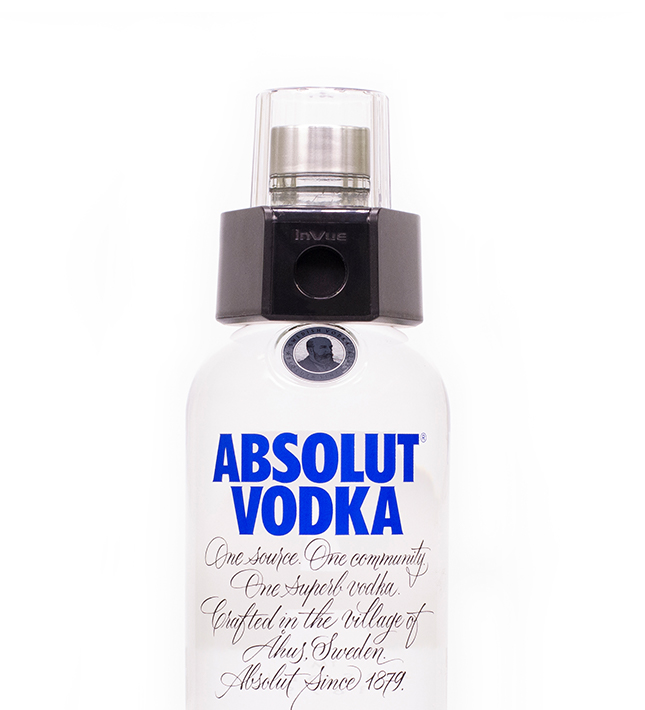

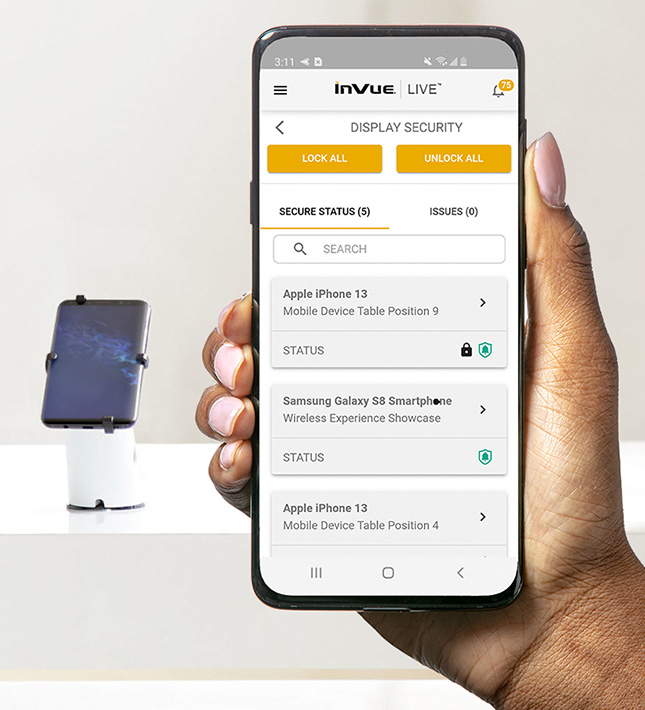

On shelf availability sensors

Other tech tools available to retailers include on-shelf availability sensors. Positioned on the shelf, these automatically alert retailers when a product is running low.

Policy and procedure

While technology is invaluable when it comes to addressing an inventory problem, it should be supported by strong policies and procedures throughout the retail environment.

These systems will address things like:

- Stock reconciliation on delivery (i.e. orders checked against inventory supplied)

- Returns policy (what happens when an item is returned, how is it accounted for, who takes receipt, when does it return to the shelf?)

- Warehouse management (where items are regularly counted, stock is kept organised, products are checked off as online orders are fulfilled, or it transitions to the store floor)

- Stock takes (How often should these occur? How are they conducted? What to do if the numbers don’t add up?)

The final word

Inventory tracking and counting has traditionally been a major challenge for retailers, but a wealth of tools are now directed at solving the inventory problem.

Combined with solid systems and procedures, they offer a solution that improves retail’s bottom line.

You can learn more about our inventory management solutions here.