What is on-shelf availability?

The practical definition of on-shelf availability is essentially what it says on the tin: the availability of a product for sale to a shopper, in the place they expect it and at the time they want to buy it. Low OSA can indicate a variety of situations:

- Lack of inventory at your location – there is no more of the product at all.

- Item is in the wrong location – shelving errors.

- Item is in stock but not on the shelf – shelf monitoring is lacking.

To your store, on-shelf availability is all about making sure customers trust that your store will meet their expectations, which is incredibly important for building loyalty. To your suppliers, it means having as much of their product on the shelf as expected, with special attention paid to their must-have SKU, sometimes referred to as their hero SKU.

How important are hero SKUs?

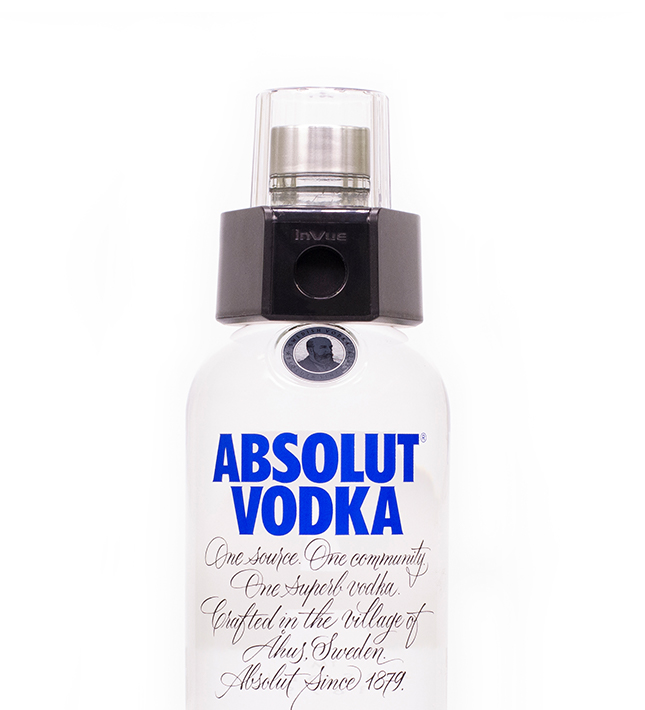

A hero SKU is the most popular product offering in a particular category and is strategic for drawing in and retaining retail customers. Hero SKUs earn their name by building their own success – they are products that are already known and loved by the public, and are likely the main reasons your customers are entering your location. Think of them as the items that are on the shopping list.

Your store relies on hero SKUs being reliably available to draw customers in, and it relies on non-hero SKUs being placed strategically nearby to drive up final sales with impulse buys.

Why is on-shelf availability important?

The higher your OSA, the more your customers will trust you as a retailer. If they frequently enter your store only to find items out of stock, they will look elsewhere. In fact, almost 40% of consumers will leave the store without buying a replacement if the exact item they came for is out of stock – and 12% will try your competitor.

Your customer loyalty and your OSA are, in some respect, two sides of the same coin. It’s very hard to convince shoppers to peruse a store with many empty shelves. Nobody wants to go through the effort of driving to a location, parking, and taking time out of their day only to arrive at the store to see that the item – or worse, multiple items – that they came for are not there.

As a retailer, this problem can be even more frustrating if the item is in stock, but put in the wrong location, or still in the stockroom. Without the proper on-shelf availability solutions to correct this issue, it can feel like chasing ghosts.

What are the different ways to track on-shelf availability?

The best way to overcome poor OSA is to first track down the problem; are items out of stock, not in the right place, or not making it out of the stockroom before the shelf is empty?

Physical Store Audits

A physical store audit is when someone, often either an in-house merchandising team or a third-party service provider, manually verifies products are placed where intended, with the correct shelf tags and signs. This can be especially helpful during store reorganizations but can quickly become expensive as the main strategy. These audits are often tied to seasonal schedules and in-store programs, or any other occasion where your store organization changes.

While they are especially useful for ensuring that display changes are intuitive, appealing, and organized, they are generally too expensive to do more than every 4-6 weeks. This means that quite a lot can change between audits, and those losses may or may not ever be accounted for.

Inventory and POS data

Some stores may find success using algorithmic solutions based on inventory and POS data, which use retailers’ inventory and POS data to predict when out-of-stock events could occur. If you have inventory of a product but sales are inconsistent, this can be enough to trigger an investigation – the first step of which is to check placement and signage around the product. This is especially true of products that sell inconsistently with no other explanation; some weeks they are going like gangbusters, other weeks only a handful (or none) are sold, and no seasonality, news or trends seems responsible.

Tracking inventory can help, but sometimes offers incomplete or misleading data – you may sell what seems like an average amount of an item, but how can you be sure it wouldn’t sell more? You may infer that a product is not selling because of an external issue (seasonality, trends, etc.) but in fact, the issue is your OSA.

Inventory reports absolutely have a place in your shelf monitoring solution, but they should be used in conjunction with more specific shelf monitoring solutions. However, if your location only stocks a few items, such as a specialty store or boutique, reports may be enough to mitigate the issue.

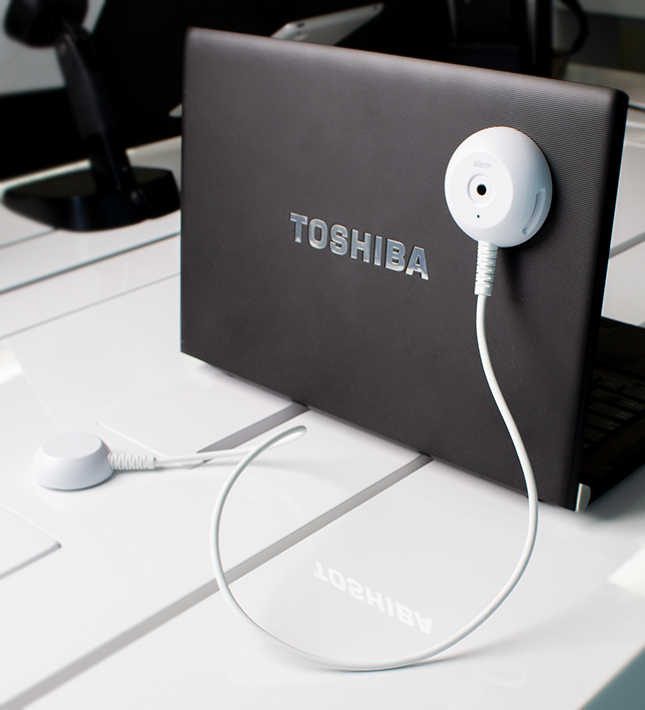

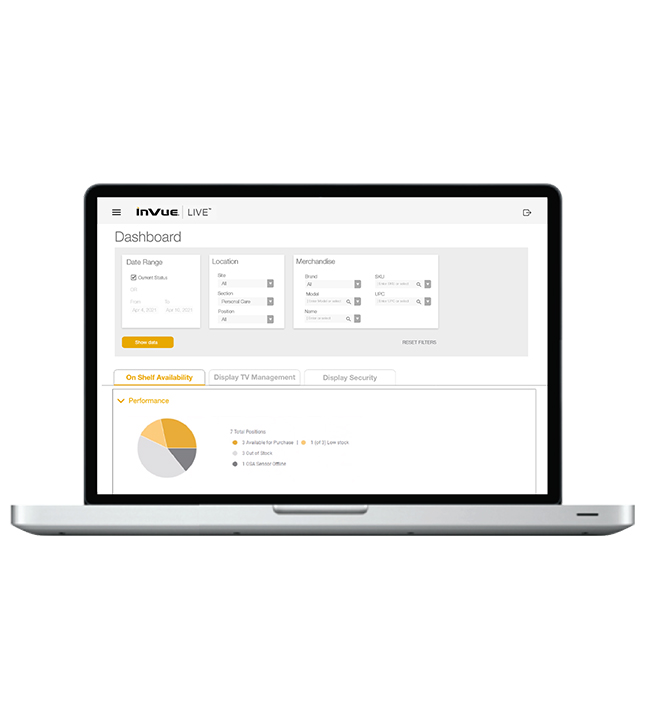

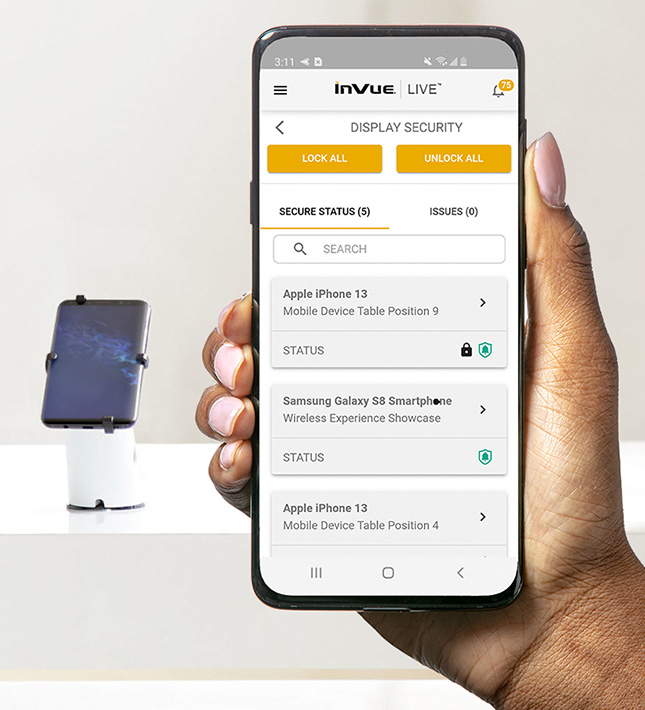

Shelf Sensors

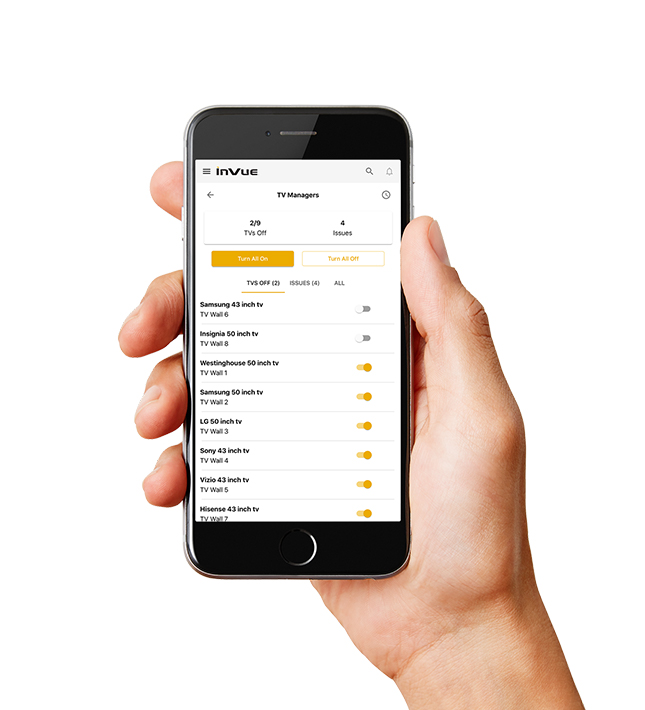

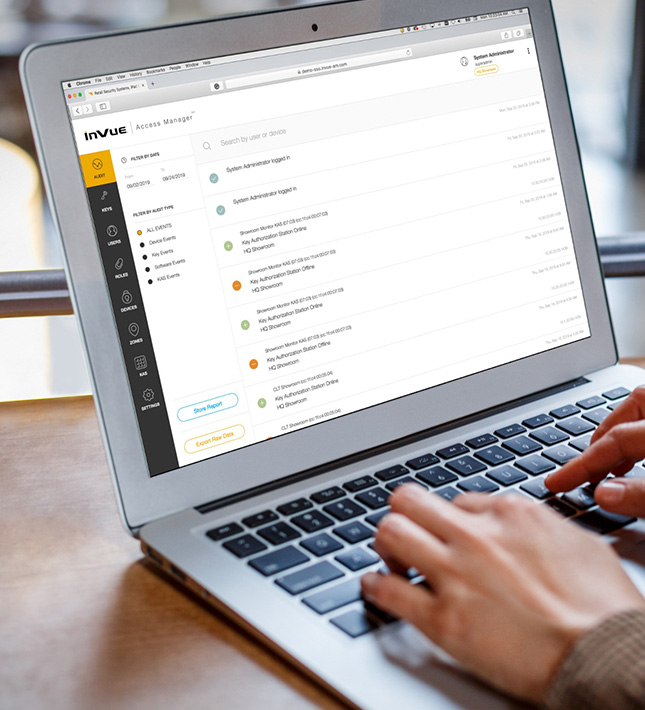

For most retail locations, especially large ones with varied inventory, the best way to track OSA is through automated, physical, and retrofittable methods in-store. This means adding shelf monitors or shelf sensors to your store displays, which can automatically alert staff when a product is out of stock. Adding sensors ensures that not only will you never be surprised to round a corner and see an empty shelf, but you’ll also be able to more easily track the impact of your increased OSA, record the frequency that shelves need to be restocked, and understand the traffic flow of your location more thoroughly.

On-shelf availability is an incredibly important factor in your overall sales, customer loyalty, and supplier relationships. The more reliably your store is stocked with both the goods your customers came in for, and the temptations that inspire them to try out new products, the more successful your store will be.

Have questions about this article? Reach out to us today for a consultation on how your store can maximise your OSA and make 2022 your best year yet!

About the Author

Derek Johnson

Derek is the Product Director of the Sales Enablement Category at InVue. Derek has 16 years of experience in developing and managing Product Lifecycle activities in the 3D Printing and now Retail Technology industries. He is an ardent product champion, customer advocate, and skilled cross-functional collaborator. When he’s not developing next-generation technology, he’s a portrait photographer and menswear brand ambassador.